15%

Increase in donations

This increase equals approximately 7,300 additional pounds donated per store per year.

40%

Trash reduction

This decrease represents approximately 82 tons per store per year removed from the landfill.

$8K

Annual savings, per store

On the Divert program, customers have saved as much as $8,200 per store per year.

The Problem

One of the largest food and drug retailers in the U.S. was seeking the right partner and solutions to reduce trash and waste, increase food donations of still edible food, and ultimately save on costs.

Our Solution

This customer looked to Divert’s diversion field team to leverage its expansive retail knowledge and experience, and help the company to reduce shrink across 260 stores in Northern California.

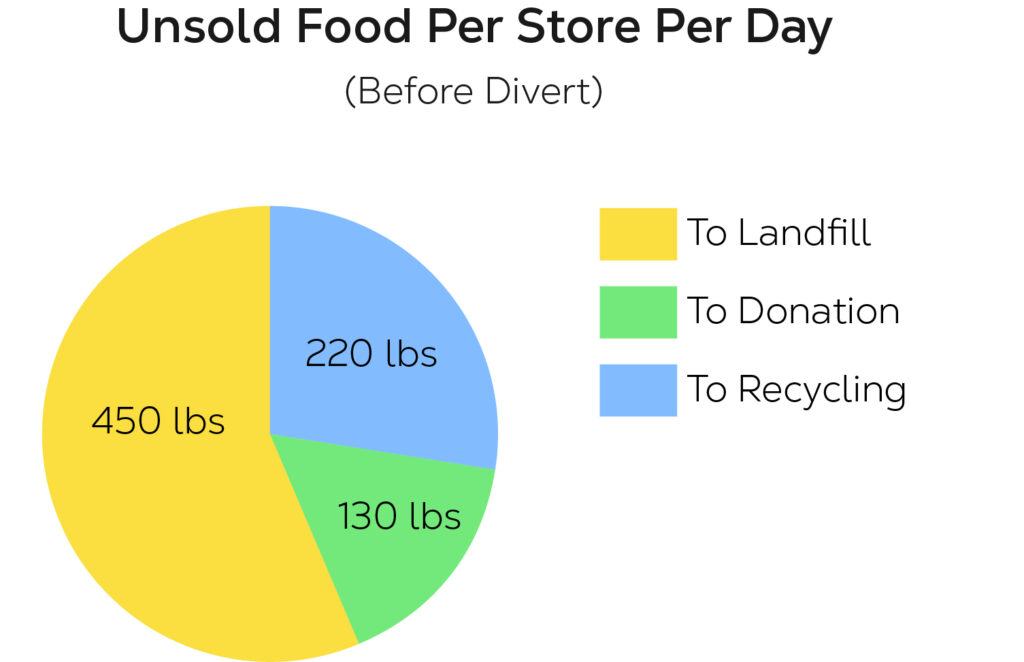

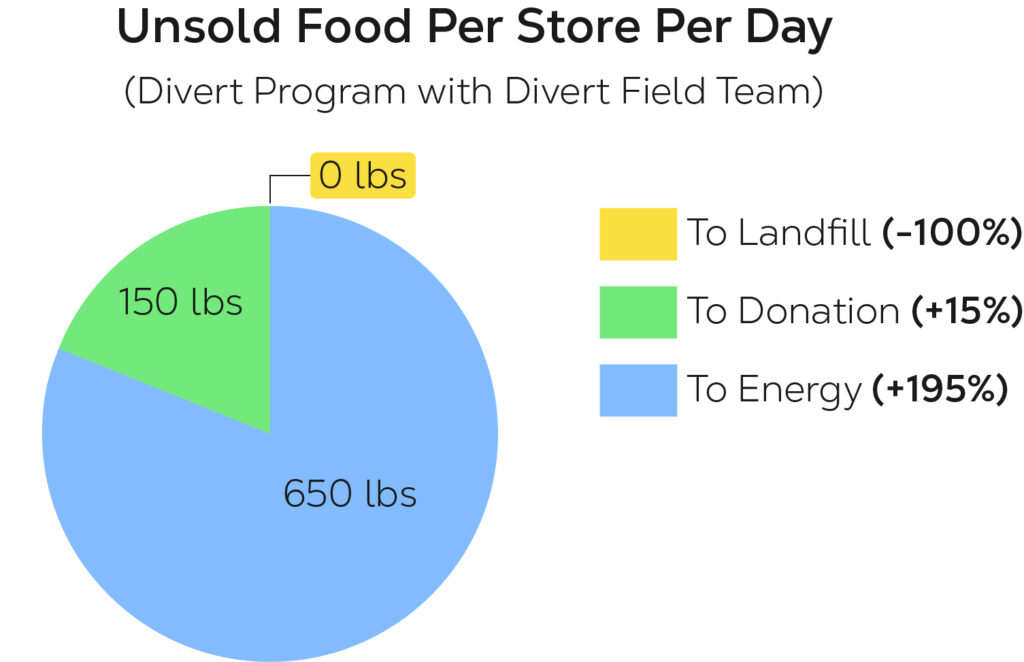

The field team was able to help develop, implement, and manage waste handling best practices and optimize operations across all of the customer’s backroom programs. To achieve this, the field team visited the customer’s stores to conduct initial waste assessments that would help to establish a baseline for the waste stream, identify opportunities for improvement, and project annual potential savings across all stores.

In addition, Divert visited stores monthly to ensure the customer’s team was following best practices across all store locations, while also coordinating directly with haulers, compactors, and other programs to continually rightsize trash, minimize shrink, and increase food donations. Based on a trash-to-sales ratio, Divert identified the top 10% of stores with the greatest opportunity for impact, and then conducted regular waste audits to continually identify areas of improvement for any stores that were falling behind.

The Results

In bringing the field team on board to provide visibility into waste operations, Divert was able to help rightsize trash at the store level and save the customer money.

As a result of implementing Divert’s solutions and diversion field team, retail customers could see the following benefits:

- 40% trash reduction

- Approximately 82 tons per store per year removed from the landfill.

- Thousands saved in trash costs

- As much as $8,200 per store per year.

- 15% increase in donations

- Approximately 7,300 additional pounds donated per store per year.